|

XR1000 |

XR1320 |

| Recorrido (X, Y, Z |

40 x 24 x 24 pulgadas

1020 x 610 x 610mm |

51,96 x 24,8 x 26,77 pulgadas

1320 x 630 x 680 mm |

| Superficie de trabajo de la mesa |

51,18 x 23,6 pulgadas

1300 x 600 mm |

55,11 x 23,62 pulgadas

1400 x 600 mm |

| Tipo de husillo |

CT40 BigPlus |

CT40 BigPlus |

| Potencia del husillo |

30 HP

22,37 kW |

40 HP

30 kW |

| Husillo |

12.000 RPM (DDS) |

12000 (ESTÁNDAR) / 15000 (OPCIONAL) |

| Velocidad de alimentación |

787 pulgadas/min |

629.9 m/min |

| Conicidad del husillo |

No. 40 |

No. 40 |

| N.° de herramientas |

30 estándar; 48/60 opcional |

30 / 40 |

| Unidad de control CNC |

FANUC Oi-MF+ |

Fanuc 0i-MF Plus 15" táctil | Heidenhain TNC 640 |

| Tamaño de la máquina (L x An. x Alt.) |

144,21 x 120 x 40,55 pulgadas

3663 x 3048 x 1030mm |

89 x 130 x 124 pulgadas

2265 x 3300 x 3165 |

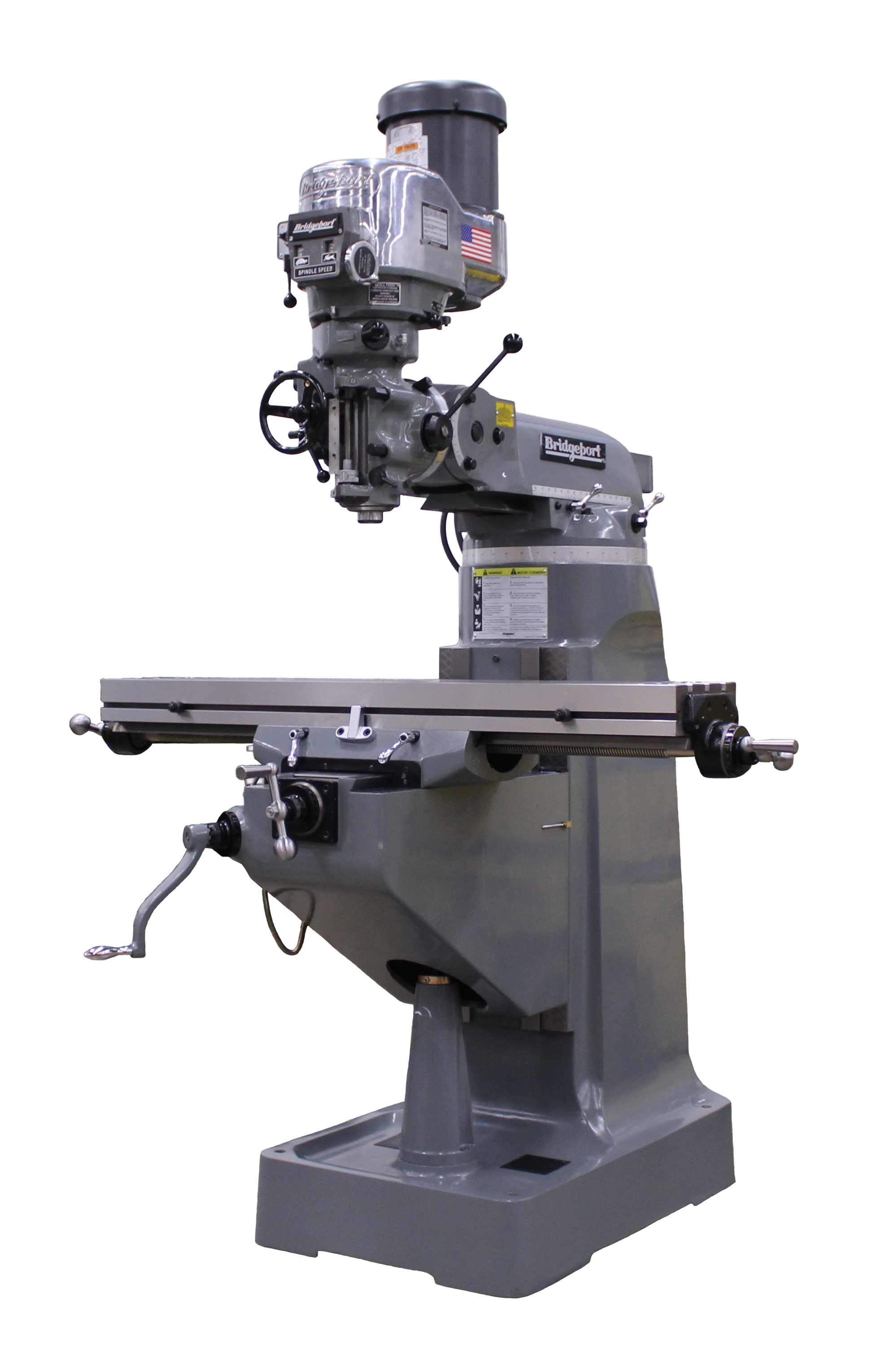

Ya sea que esté mecanizando piezas de trabajo simples, moldes y matrices de calidad o piezas prismáticas complejas, los centros de mecanizado de la serie Bridgeport XR son ideales para su operación. Las máquinas Bridgeport XR satisfacen fácilmente los requisitos de mecanizado de componentes de precisión y producción más exigentes en los sectores aeroespacial, automotriz, de fabricación de moldes y herramientas, ingeniería eléctrica y petróleo/gas, y más. Cuando se necesita más recorrido en el eje X, entonces el XR1000 satisface. Estas sólidas máquinas ofrecen una dureza y rigidez excepcionales para brindar resultados sobresalientes en los entornos de producción más exigentes. Son especialmente adecuados para mecanizar metales exóticos, como titanio y Nimonics (aleaciones con base de níquel). Para aumentar aún más la productividad, los VMC de la serie XR están configurados para el mecanizado de 4 ejes con una interfaz opcional y una mesa giratoria.

- AICC con 200 bloques de anticipación

- Compensación térmica

- Eje de accionamiento directo de aceite/aire 12K

- Big Plus CAT 40

- Velocidad del husillo de 12 000 rpm

- Husillos cónicos CT40 o BT40

- Husillo cónico frontal BIG-PLUS

- Barra de tracción de alta retención

- Compensación térmica

- Transportador de virutas con lavado de virutas

- Chorro de aire del cortador

- Roscado rígido

- Precableado de 4.º eje

FANUC 0iMF-PLUS

- 15″ LCD Color Display

- Programmable Data Input

- PCMCIA Card Slot

- Workpiece Coordinate System

- Manual Pulse Generator (Handwheel)

- Coordinate System Rotation

- Roscado rígido

- Tool Life Management

- Tool Length compensation

- Background Editing

- Ethernet Ready/ RS232 Ready/ USB Slot

- Additional Workpiece Coordinate System

- Manual Guide i

Heidenhain TNC 640 HSCI

- Pantalla de panel plano TFT en colores de 15 in con teclas programables

- Disco de estado sólido de memoria de programa (mínimo 21 GB)

- Interpolación: línea recta en 4 ejes, círculo en 2 ejes, hélice: combinación de movimiento circular y lineal

- Tiempo de procesamiento de bloques de 0,5 ms

- Interfaces de datos

- Programación conversacional de Heidenhain según ISO

- Compensación de herramientas

- Varias tablas de herramientas con cualquier número de herramientas

- Tablas de datos de corte

- Velocidad constante de contorneado

- Programación de contorno libre FK

- Saltos de programa

- Ciclos fijos

- Transformaciones de coordenadas

- Parámetros Q

- Ayudas de programación

- Captura de posición real

- Gráficos de verificación

- Gráficos de programación

- Gráficos de ejecución del programa

- Tiempo de mecanizado

- Regreso al contorno

- Tablas de datos

- Mesas de paletas

- Ciclos de sonda de contacto

- Tabla preestablecida

Las características de programación conversacional ofrecidas en el control CNC son el producto estándar del fabricante del control CNC que pueden no ser compatible con todas las funciones de la máquina. Se recomienda que el usuario final consulte la documentación del sistema de control o se comunique con el fabricante del control para obtener más detalles acerca del uso o la personalización.

La serie XR abarca los centros de mecanizado verticales más sofisticados y versátiles del mundo. Los VMC de la serie XR son ideales para adaptarse a numerosas industrias:

- Herramienta y matriz/prototipado rápido

- Aeroespacial

- Pharmaceutical

- Industria automotriz

- Grandes talleres y OEM