|

SERIES 1 |

SERIES 1 CNC |

| X-Axis Table Travel |

|

| Without Power Feed |

36" (914mm) |

N/A |

| With Power Feed |

33" (838mm) |

33" (838mm) |

| Y Axis Travel |

|

| Without Power Feed |

12" (306mm) |

| With Power Feed |

12" (306mm) |

| Avance de la pluma |

5" (127mm) |

4.03" (102mm) |

| Knee Travel |

16" (406mm) |

| Avance del vástago |

12" (306mm) |

| Throat Distance |

|

| Min |

6.75" (171mm) |

| Max |

18.75" (476mm) |

| Table to Spindle Nose |

|

| Min |

2.5" (64mm) |

| Max |

18.25" (463mm) |

| TABLE |

|

| Overall Size |

9" x 49" (299 x 1245mm) |

| Superficie de trabajo |

9" x 49" (299 x 1245mm) |

| Number of T-Slots |

3 |

| T-Slot Centers |

2.5" (64mm) |

| Tamaño de la ranura T |

0.625" (16mm) |

| Height Above Floor Maximum |

47.25" (1200mm) |

| Weight of Workpiece Maximum |

750lbs. (340kgs) |

| SPINDLE CONSTRUCTION |

|

| Diámetro del husillo |

1.875" (48mm) |

| Diámetro de la caña |

3.375" (86mm) |

| SPINDLE MOTOR HP |

|

| 30 Min Duty Rated |

3HP |

| Continuous |

2HP |

| SPINDLE TAPER |

|

| Estándar |

R-8 |

| opcional |

NMTB30 |

| SPINDLE SPEED RANGE |

|

| Low Range |

60 - 500 RPM |

| High Range |

500 - 4200 RPM |

| QUILL FEED RANGE (3) |

and 2 Axis CNC |

3 Axis CNC |

| Range #1 |

0.0015 "/rev |

Program Range |

| Range #2 |

0.003"/rev |

0-100 IPM |

| Range #3 |

0.006"/rev |

|

| MACHINING CAPACITIES |

|

| Power Quill Feed Drilling (mild steel) |

3/8" (9.5mm) |

| Miling (mild steel) |

2 CI/min |

| Boring Range (mild steel) |

6" Dia (152mm) |

| POSITIONING |

|

| Feedrate Range |

N/A |

0-100 IPM |

| Minimum Increment |

N/A |

0.0001" |

| SPACE AND WEIGHT |

|

| Floor Area |

84" x 120" (2140 x 3048mm) |

| Altura |

87" (2210mm) |

| Net Weight |

1930lbs (875kgs) |

| Shipping Weight |

2075lbs (941kgs) |

| ELECTRICAL SUPPLY |

|

| Input Power |

208/230/460 |

208/230/460 3 phase 50/60 cycle |

|

3 phase 50/60 cycle |

110/1/60 for Control |

| Power Capacity |

4 KVA |

4 KVA / 15Amp CTRL |

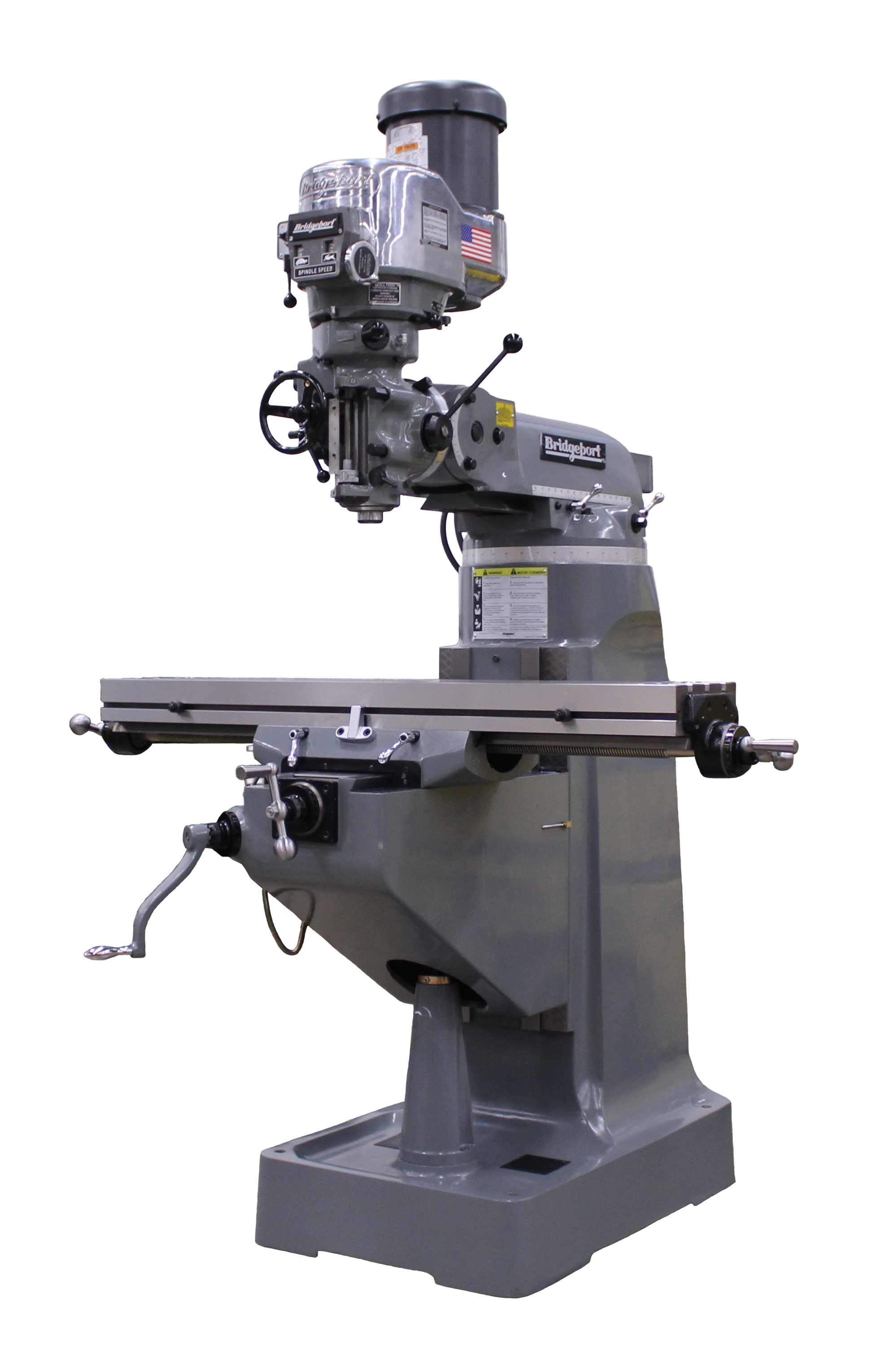

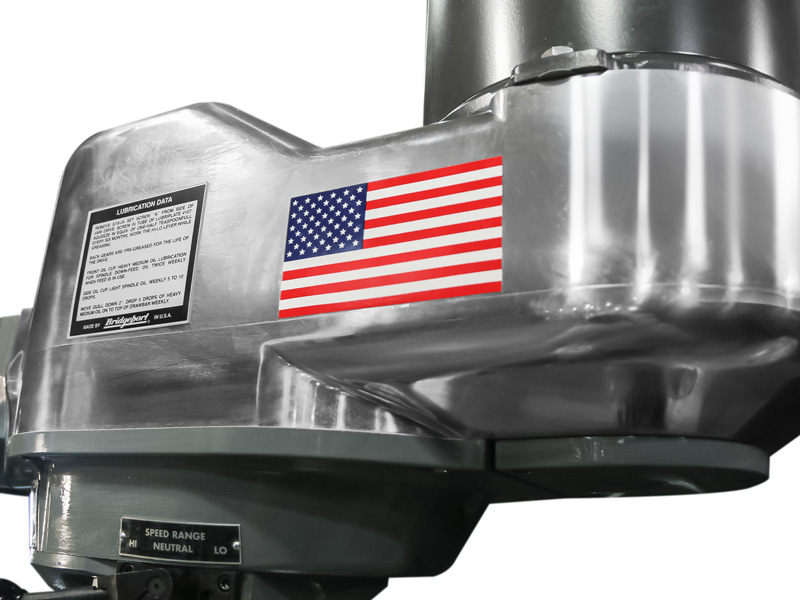

El La fresadora estándar de la serie I de Bridgeport is the original milling, drilling and boring machine. The Bridgeport Series I Knee Mill is the most popular mill ever made with over 400,000 machines built over the past 70-plus years.

Características estándar

- Patented 2J Head gives unique air cooling for spindle bearings

- Hardened & Scaped, X, Y & Z Ways

- Scraped gibs for alignment

- T-slots are ground to provide reference edge for positioning your workplace

- Hardened & Scraped Table Surface

- Hardened & Ground Spindle

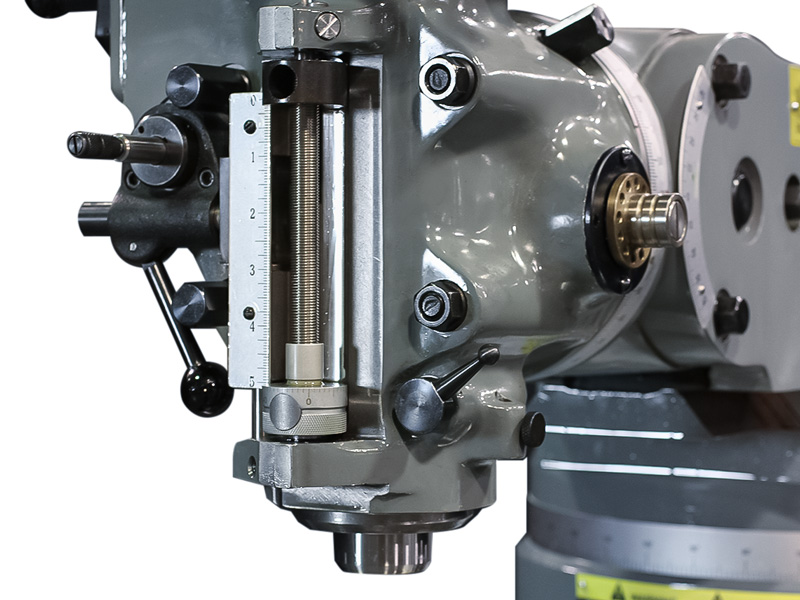

- Chromed & Ground Quill

- Chromed X, Y, & Z Leadscrews

- ABEC 7/CP4 Spindle Bearings

- One-piece way wipers

- 7/16”-20 Imperial Drawbar R8

- 3 / 2 Hp AC Motor (3Hp 30 minute duty/ 2Hp continuous)

- Variable Speed Drive

- Worm gear angular positioning of head in two directions

- Lever-operated manual rapid quill movement

- Handwheel for fine quill feed

- Adjustable automatic feed disengagement for quill feed in both directions

- Micrometer depth stop

- Reversing switch for clockwise or counter clockwise operation

- R8 Spindle taper

- Spindle Brake (Hand operated)

- One-shot lubrication

- Leveling bolts and pads

- Tool Kit, Test and Accuracy Chart

- Operations Manual/Parts List

- Series 1 Standard 208/230 or 460 3 Phase (other voltages require a transformer) Control requires separate 110/1/60 Volt Line.

Características opcionales

- Acu-rite Solutions ® MillPWR G2 CNC Control

- Lectura digital de 2 o 3 ejes

- Power Drawbar for R-8 or #30 Quick-Change Spindle (USA Manufactured)

- Worklight Electrics—NFPA/NEMA-12 Standards, optional NRTL testing

- Coolant Chip Pan

- Enclosed Base Coolant System w/On-Off Switch

- 4” Column Riser Block

- 6” Column Riser Block

- 8” Column Riser Block

- Knee Servo Feed (USA Manufactured)

- Knee Scale for MillPWR

- R8 Milling Chuck Kit w/11 ER Collets

- R8 Metric Set 2mm by 1mm, 19 Collets

- R8 Inch Collet Set 1/8 to 7/8 by 32nds, 25 Collets

- R8 Inch Collet Set 1/8 to 7/8 by 1/16ths, 13 Collets

- R8 Inch Collet Set 1/8 to 3/4 by 1/8ths, 6 Collets

- 12pc. R8 Collet Rack

- 1/2″ R8 Shell Mill Holder

- 3/4″ R8 Shell Mill Holder

- 1″ R8 Shell Mill Holder

- R8 End Mill Adapter Set 3/16 – 1 1/4 (8pcs.)

- 52 Piece Clamping Kit

- Kurt 6” Vise

- Kurt 6” Swivel Base

- Vise Step Key Kit 11/16 x 5/8 (set of 2)

- 1/2″ Keyless Drill Chuck

- 1/8″ to 5/8″ Keyless Drill Chuck

- LED Work Light w/3Pin 110V Plug

- Coolant Mist System 1 Gal

To see the full range of accessories available, please Contáctenos to receive a quote.

La fresadora universal estándar Bridgeport serie I es la máquina de fresado, taladrado y mandrinado más utilizada en el mundo. Se puede encontrar en talleres de trabajo de todo el mundo sirviendo en innumerables capacidades.